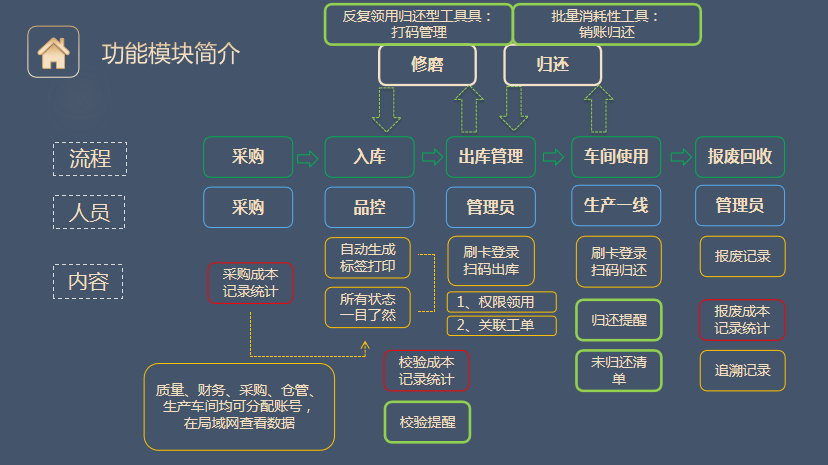

System function module

Use process

The tool room and intelligent cabinet can store consumable tools, coding tools and measuring tools.

1. Collecting consumable tools in tool room

The employees of the production workshop go to the tool room, swipe their card to log in to the system, and inform the name, model and quantity of the received tools. After the administrator enters the model and quantity, they will be taken out to the collector.

The system automatically records the collection information such as corresponding personnel, time, model and quantity.

2. Code type tools and tools for tool room collection

After scanning the two-dimensional code of the tools used in the workshop, the manager will take out the two-dimensional code of the tools used, scan the number of the tools used, and then log in to the production room, and the manager will automatically record the number of the tools used, scan the number of the tools and so on.

The system automatically records the corresponding personnel, time, tools and other collection information.

3. Tool chamber returns consumable tools

The staff of the production workshop go to the tool room, swipe their card to log in to the system, return the received tools, jump out of the unreturned list, and after the administrator checks that there is no damage and can continue to use, click the corresponding collection record, pop out the dialog box (three options return, grinding and scrapping), click return, enter the quantity for write off, and put it on the shelf.

If it is found that the returned tool has been worn and needs grinding, click grinding; If the service life has expired and needs to be scrapped, click scrap. The system automatically records the return information such as corresponding personnel, time, model and quantity.

4. The tool room returns coded tools and tools

The staff of the production workshop go to the tool room, swipe the card to log in to the system and return the received tools. After the administrator checks that there is no damage and can continue to use, the two-dimensional code in the label is directly scanned to jump out the corresponding tool information, and there are two options: return and grinding. The administrator clicks return, jumps out of the warehouse location information and ends the shelf placement.

If it is found that the returned tool has been worn and needs grinding, click grinding; If the service life has expired, it needs to be scrapped. Therefore, the unit price of such tools is generally high and needs to be reviewed or verified. The administrator will scrap them in another special process.

The system automatically records the return information such as corresponding personnel, time, model and quantity.

5. Intelligent tool cabinet for collecting consumable tools

Employees in the production workshop go to the smart cabinet, swipe their card to log in, click collect, and enter the corresponding model or name to support the search and query function. After the drawer is turned on, the corresponding number of tools will be automatically recorded and the system will automatically jump out.

6. Code printing tool for intelligent cabinet collection

The employees of the production workshop go to the smart grid cabinet, swipe the card to log in, enter the model query, and after the cabinet door is automatically opened, take out the cutting tools and measuring tools, scan the QR code, confirm the second time, generate the picking record, and close the cabinet door.

7. Intelligent tool cabinet consumable tool return

The employees in the production workshop go to the smart cabinet, swipe their card to log in, click return, and pop up their own to be returned list. After selecting the record, their own special cabinet door will automatically open, put in and close the cabinet door.

The system will automatically generate return records, and the administrator will check the return list regularly.

8. Return of coded (borrowed) tools and measuring tools

Swipe the card to log in, directly scan the QR code, the door of the storage cabinet will open automatically, and the return record will be generated after putting in.

9. Consumable tool warehousing

Generate a receipt document in the system background and replenish the goods to the corresponding warehouse location. At the smart cabinet, you can click stock in, enter the stock in number, open the cabinet door and count automatically.

10. Code type tool warehousing

In the background of the system, produce the warehousing order, edit the corresponding separate warehouse location, produce the QR code label, and replenish the goods to the corresponding shelf. At the smart cabinet, you can scan the code directly and open the cabinet door to put it in.

Brief function introduction

1. Cost statistics

It can count the warehousing purchase cost, grinding or calibration cost and scrap cost. It can be associated with machine tools, work orders, products and processes to analyze the corresponding costs respectively. After docking with ERP, it supports the overall analysis and statistics of production line, personnel, work orders and other related costs, such as the actual tool cost of a work order, the comparison of horizontal personnel and machine tool processing cost, etc.

2. Verification reminder

You can filter and query the list to be verified or abnormal list to be verified for tool grinding and measuring tool verification.

3. Inventory query

You can query the inventory status, quantity, location information, model and specification of consumable materials and coded materials respectively, view the last collection record, and filter different statuses such as inventory, collection, verification and scrap.

4. Unreturned reminder

The overdue reminder time of each coding tool can be set. If it is overdue, the reminder can be displayed in the report

5. Tool destination query and tracing

The collecting time and information of the corresponding tool can be queried retroactively,

6. Real time record of collection and return

Collection and return records are generated in real time, which can be queried but not changed manually

7. System docking

An interface is reserved to connect with ERP or other management systems. In the LAN, data reports and other information can be viewed remotely through other computers to facilitate the management to view and maintain.

8. Warehouse shelf and intelligent cabinet goods maintenance

Support the management of shelf goods and intelligent cabinet location information.

9. Department authority management

It supports the management of department permissions and personnel permissions. Different roles are set to control the front-end collection, return, receipt, verification issue, verification return and process settings. For example, workshop personnel only have the permission to collect and return, administrators have the permission to collect, return, receipt and verify issue and receipt, and super administrators have all the permissions.

Support the permission setting of background reports and settings. Different roles have the permission to modify, view and delete.

Function main interface display description

It is divided into several modules, which can set the operation permissions of employees. For example, the collecting personnel in the workshop only have the permissions of collecting, tool return and tool return, and others can only be opened by the administrator.

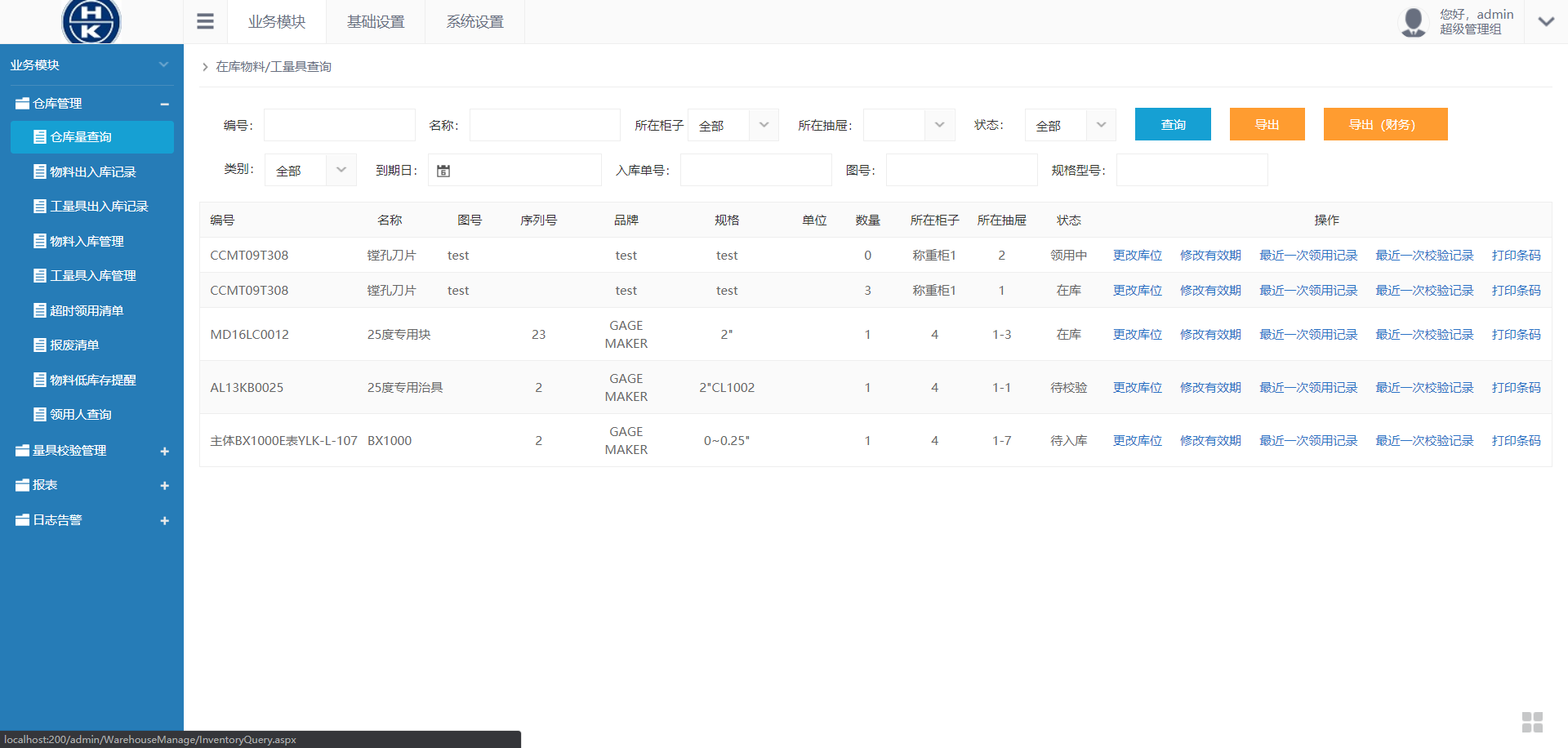

Description of inventory status interface

The corresponding list can be queried and filtered by material number, inventory status (in stock, to be received, issue collection, abnormal to be verified grinding, verification grinding), warehouse location, after receipt document, drawing number, etc.

It supports the functions of changing the warehouse location, modifying the validity period, viewing the last collection record, the last verification and grinding record, and reprinting if the QR code is lost.

Display description of issue / receipt record interface

It is divided into consumption type tool stock in and stock out records and repeated collection return type tool stock in and stock out records, which can be queried and filtered by material number, specification, serial number, personnel, location, etc

All receipt / issue records can be exported and cannot be changed after real-time generation.

|

15050151202 Free service hotline |

|

Follow us Please scan the official account |

Copyright ? HRC Automation(Suzhou)Co.,Ltd 備案號:蘇ICP備19026496號